Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry

Related Articles: Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry

Introduction

With great pleasure, we will explore the intriguing topic related to Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry

- 2 Introduction

- 3 Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry

- 3.1 What is E-Coating?

- 3.2 The Science Behind E-Coating

- 3.3 Benefits of E-Coating for Jewelry

- 3.4 Types of E-Coatings for Jewelry

- 3.5 The Application Process

- 3.6 FAQs: E-Coating for Jewelry

- 3.7 Tips for Choosing E-Coated Jewelry

- 3.8 Conclusion

- 4 Closure

Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry

In the world of jewelry, where beauty and durability intertwine, a crucial element often goes unnoticed: the protective coating. This invisible shield, known as an e-coating, plays a vital role in safeguarding the precious metals and enhancing the longevity of your beloved pieces.

This comprehensive guide delves into the intricacies of e-coatings, exploring their composition, application, and the benefits they offer to jewelry. We will shed light on the science behind this protective layer, uncovering its significance in preserving the brilliance and integrity of your jewelry for years to come.

What is E-Coating?

E-coating, short for electro-coating, is a sophisticated process that utilizes an electric current to deposit a thin, uniform layer of protective material onto a substrate. In the context of jewelry, the substrate is typically a metal like gold, silver, or platinum. The protective material, often a polymer or a combination of polymers, forms a robust barrier against various environmental aggressors.

The Science Behind E-Coating

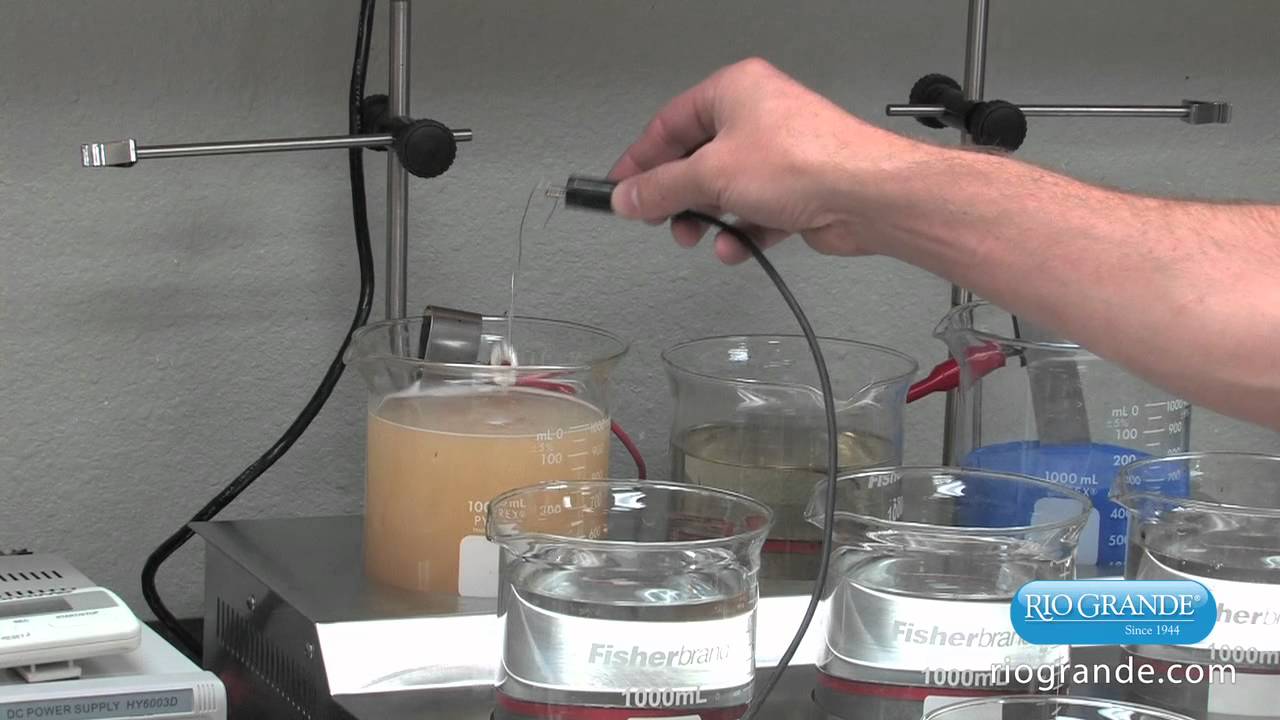

The process of e-coating involves immersing the jewelry piece in a bath containing a specialized solution of the chosen protective material. A direct current is then applied, causing the charged particles in the solution to migrate towards the jewelry, where they adhere to the surface. This electrostatic attraction ensures a consistent and even application of the coating.

Benefits of E-Coating for Jewelry

E-coatings offer a multitude of advantages for jewelry, enhancing its durability, aesthetic appeal, and overall longevity. Here are some key benefits:

-

Protection Against Corrosion and Tarnish: E-coatings act as a barrier against the damaging effects of oxidation and tarnishing, which are common issues for metals like silver and gold. This protective layer prevents the formation of undesirable tarnish, preserving the original luster and shine of the jewelry.

-

Enhanced Scratch Resistance: E-coatings provide a tough, resilient surface that can withstand scratches and abrasions. This is particularly beneficial for everyday wear, as it helps prevent the jewelry from getting marred or damaged.

-

Improved Durability and Longevity: The protective layer offered by e-coatings significantly enhances the durability of jewelry, extending its lifespan and ensuring that it remains beautiful and intact for years to come.

-

Water Resistance: E-coatings can be formulated to provide varying levels of water resistance, making the jewelry suitable for everyday wear, even in humid environments.

-

Enhanced Aesthetics: E-coatings can be applied in various finishes, from glossy to matte, allowing for customization and enhancing the aesthetic appeal of the jewelry.

Types of E-Coatings for Jewelry

E-coatings for jewelry come in various forms, each offering specific benefits and tailored to different applications. Here are some common types:

-

Acrylic E-Coatings: These coatings are known for their excellent scratch resistance, durability, and affordability. They are commonly used on silver and gold jewelry.

-

Epoxy E-Coatings: Epoxy e-coatings offer superior chemical resistance and durability, making them ideal for jewelry exposed to harsh environments or chemicals.

-

Polyurethane E-Coatings: Polyurethane e-coatings provide a high level of abrasion resistance and flexibility, making them suitable for jewelry that is frequently worn and subjected to impact.

-

Ceramic E-Coatings: Ceramic e-coatings are known for their exceptional hardness and scratch resistance, providing a durable and long-lasting protective layer.

The Application Process

The application of e-coatings to jewelry typically involves a multi-step process:

-

Pre-Treatment: The jewelry is thoroughly cleaned and prepared to ensure optimal adhesion of the coating. This may involve processes like degreasing and etching.

-

E-Coating Deposition: The jewelry is then immersed in the e-coating bath and subjected to an electric current, allowing the protective material to deposit onto the surface.

-

Curing: The coated jewelry is then subjected to a curing process, typically involving heat, to solidify and harden the coating.

-

Post-Treatment: The jewelry may undergo additional finishing processes, such as polishing or buffing, to achieve the desired aesthetic appearance.

FAQs: E-Coating for Jewelry

1. Is e-coating safe for jewelry?

E-coating is generally considered safe for jewelry, as the materials used are non-toxic and do not react with the metals. However, it is always advisable to inquire about the specific materials used and their safety profile from the jeweler or manufacturer.

2. Does e-coating affect the appearance of the jewelry?

E-coatings are typically applied in thin layers, which do not significantly alter the appearance of the jewelry. However, some coatings may have a slight sheen or a matte finish, depending on the desired aesthetic.

3. How long does an e-coating last?

The lifespan of an e-coating depends on the specific type of coating, the quality of application, and the wear and tear it experiences. However, with proper care, an e-coating can last for several years, protecting the jewelry from damage.

4. Can e-coating be applied to all types of jewelry?

E-coatings can be applied to various types of jewelry, including gold, silver, platinum, and other precious metals. However, it is important to consult with a jeweler or manufacturer to determine the suitability of e-coating for a specific piece.

5. How do I care for jewelry with an e-coating?

Jewelry with an e-coating should be handled with care to ensure its longevity. Avoid exposing it to harsh chemicals, extreme temperatures, and abrasive materials. Regular cleaning with a soft cloth and mild soap can help maintain the coating’s effectiveness.

Tips for Choosing E-Coated Jewelry

- Research the coating: Inquire about the type of e-coating used and its specific properties, such as scratch resistance, water resistance, and chemical resistance.

- Consider the wear and tear: Choose a coating that is suitable for the intended use of the jewelry. For everyday wear, a durable and scratch-resistant coating is recommended.

- Check the warranty: Some jewelers offer warranties on e-coated jewelry, providing peace of mind and assurance of quality.

Conclusion

E-coating plays a crucial role in safeguarding the beauty and longevity of jewelry. This protective layer acts as an invisible shield, protecting the precious metals from corrosion, tarnishing, and scratches. By understanding the benefits and application process of e-coatings, you can make informed decisions when choosing jewelry and ensure that your treasured pieces remain beautiful and intact for years to come. With proper care and attention, your e-coated jewelry will continue to shine, reflecting your personal style and adding a touch of elegance to your life.

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Protective Shield: A Deep Dive into E-Coatings for Jewelry. We thank you for taking the time to read this article. See you in our next article!