The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance

Related Articles: The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance

Introduction

With great pleasure, we will explore the intriguing topic related to The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance

- 2 Introduction

- 3 The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance

- 3.1 Understanding the Essence of Wheeler Manufacturing

- 3.2 The Wheeler: A Masterpiece of Engineering

- 3.3 The Benefits of Wheeler Manufacturing

- 3.4 Unveiling the Process: A Step-by-Step Guide

- 3.5 The Importance of Expertise and Skill

- 3.6 Beyond the Basics: Exploring the Artistic Potential

- 3.7 Wheeler Manufacturing: A Legacy of Craftsmanship

- 3.8 Frequently Asked Questions about Wheeler Manufacturing Jewelry

- 3.9 Tips for Choosing Wheeler Manufacturing Jewelry

- 3.10 Conclusion: A Legacy of Precision and Elegance

- 4 Closure

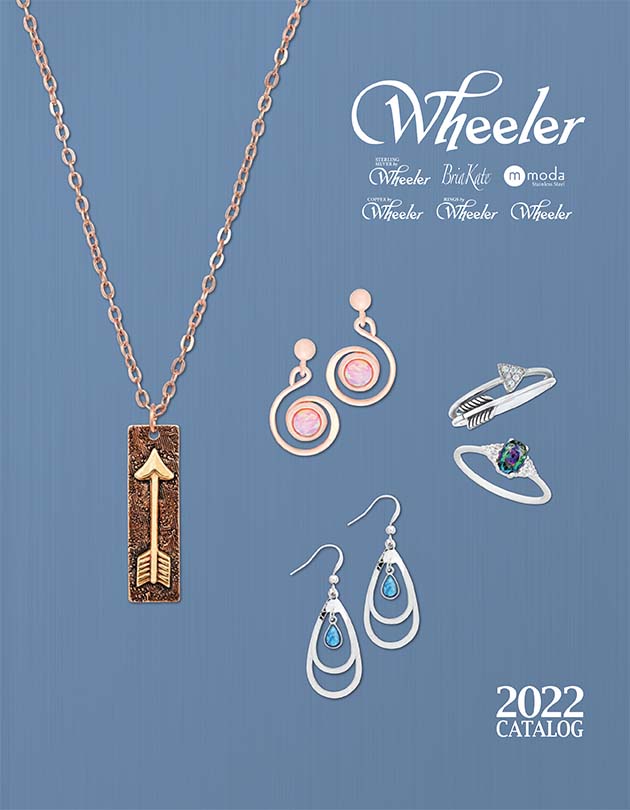

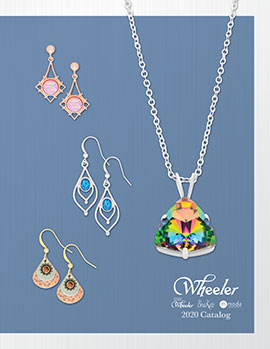

The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance

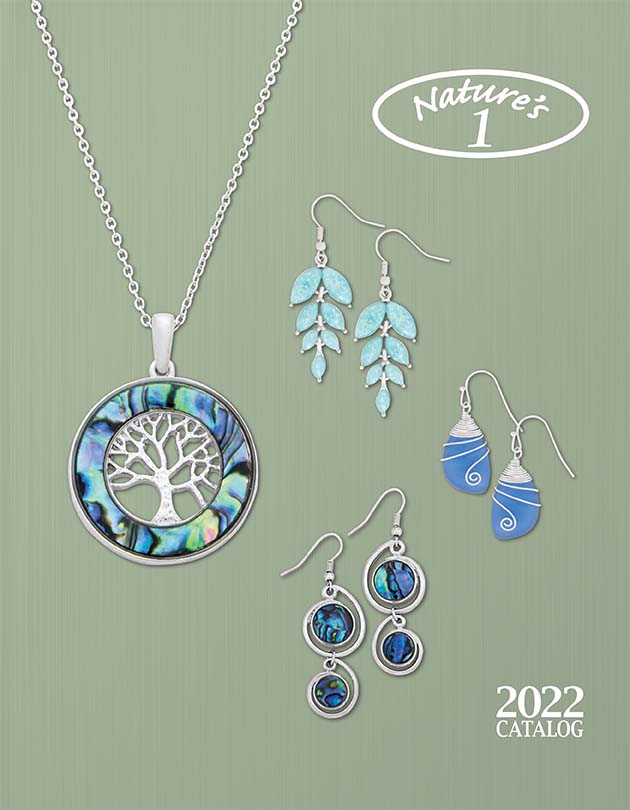

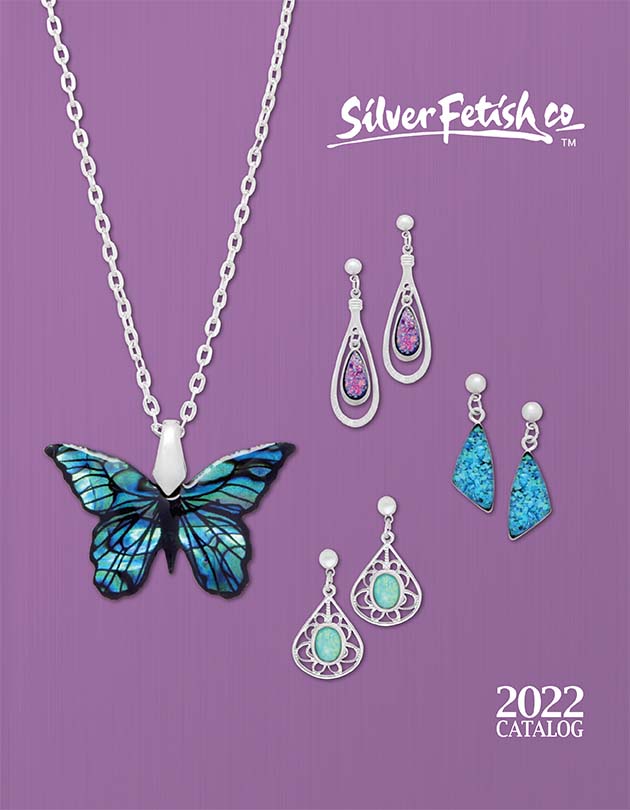

Jewelry, a timeless art form, transcends mere adornment. It embodies stories, emotions, and cultural heritage, becoming cherished heirlooms passed down through generations. While the artistry of jewelry design is undeniable, the creation of these intricate pieces relies heavily on the precision and skill of manufacturing. Among the diverse methods employed, wheeler manufacturing stands out as a technique that blends traditional craftsmanship with modern technology, resulting in exquisite jewelry with unparalleled detail and durability.

Understanding the Essence of Wheeler Manufacturing

Wheeler manufacturing, also known as wire wrapping, is a jewelry-making technique that utilizes a specialized tool – the wheeler – to shape and manipulate metal wire into intricate designs. This process involves meticulously winding the wire around a mandrel, a cylindrical tool that serves as a template for the desired shape. The resulting piece is then carefully polished and finished, revealing a stunning interplay of texture and light.

The Wheeler: A Masterpiece of Engineering

The heart of wheeler manufacturing lies in the wheeler itself. This precision instrument is a combination of a rotating spindle, a mandrel, and a series of dies. The spindle, powered by an electric motor, rotates the wire at high speed, while the mandrel provides the shape and form. The dies, strategically positioned along the mandrel, guide the wire and create specific patterns and textures.

The design of the wheeler allows for remarkable flexibility. It can accommodate a wide range of wire gauges, from delicate strands to thicker wires, enabling the creation of intricate details and robust structures. The speed and precision of the machine ensure consistent results, minimizing human error and maximizing efficiency.

The Benefits of Wheeler Manufacturing

Wheeler manufacturing offers a unique blend of artistic freedom and technical precision, resulting in several key benefits:

- Intricate Designs: The intricate patterns and textures achieved through wheeler manufacturing are unmatched by other techniques. The ability to manipulate the wire with such precision allows for the creation of intricate details, delicate filigree, and complex geometric patterns.

- Durability: The process of winding the wire around the mandrel creates a robust structure that is resistant to bending and breakage. This makes wheeler-manufactured jewelry ideal for everyday wear and long-lasting beauty.

- Versatility: Wheeler manufacturing can be applied to a wide range of metals, including silver, gold, copper, and even titanium. This versatility allows for the creation of jewelry in a variety of styles and finishes, catering to diverse tastes.

- Unique Textures: The dies used in the process can create a range of textures, from smooth and polished to rough and hammered. This allows for the creation of jewelry with a unique character and visual appeal.

- Efficiency: Wheeler manufacturing offers a significant advantage in terms of speed and efficiency. The machine-driven process allows for the rapid creation of multiple pieces with consistent quality, making it an ideal choice for both small-scale artisans and large-scale production.

Unveiling the Process: A Step-by-Step Guide

The process of wheeler manufacturing is a meticulous dance between artistry and technology. Here’s a step-by-step guide:

- Design and Planning: The process begins with a clear vision of the desired design. The jeweler sketches out the piece, considering the desired shape, size, and texture.

- Wire Selection: The appropriate wire gauge and material are chosen based on the design and desired effect.

- Mandrel Preparation: The mandrel, which serves as the template for the shape, is carefully prepared and secured in the wheeler.

- Wire Winding: The wire is fed into the wheeler, where it is rotated at high speed around the mandrel. The dies guide the wire, creating the desired patterns and textures.

- Finishing: Once the wire is completely wound, the piece is removed from the mandrel and carefully polished and finished. This may involve sanding, buffing, and applying a protective coating.

The Importance of Expertise and Skill

While the wheeler is a powerful tool, it is only as good as the skill of the jeweler using it. Mastering the art of wheeler manufacturing requires years of practice, patience, and a keen eye for detail.

Jewellers must have a deep understanding of the properties of different metals, the capabilities of the wheeler, and the intricacies of design. They must also be able to anticipate potential problems and troubleshoot effectively.

Beyond the Basics: Exploring the Artistic Potential

While wheeler manufacturing is often associated with intricate wirework and geometric designs, its potential extends far beyond these traditional applications. Modern jewellers are using the technique to create innovative pieces that push the boundaries of design and craftsmanship.

- Three-Dimensional Forms: Wheeler manufacturing can be used to create intricate three-dimensional forms, such as spirals, coils, and even miniature sculptures.

- Organic Shapes: The technique is well-suited to crafting organic shapes, such as leaves, flowers, and animal forms.

- Mixed Media: Wheeler manufacturing can be combined with other techniques, such as casting, soldering, and gemstone setting, to create truly unique and complex pieces.

Wheeler Manufacturing: A Legacy of Craftsmanship

Wheeler manufacturing has a rich history dating back centuries. The technique was originally developed for crafting intricate metalwork, such as chains and decorative elements. Today, it remains a vital part of the jewelry-making process, particularly in the creation of fine jewelry, custom pieces, and artistic creations.

Frequently Asked Questions about Wheeler Manufacturing Jewelry

1. What makes wheeler manufacturing unique?

Wheeler manufacturing stands out for its ability to create intricate designs and textures with exceptional precision and durability. The process allows for a wide range of creative possibilities, from delicate filigree to robust structures.

2. Is wheeler manufacturing jewelry expensive?

The cost of wheeler manufacturing jewelry can vary depending on the complexity of the design, the materials used, and the jeweler’s experience. However, the technique often results in high-quality, durable pieces that can be considered an investment in timeless beauty.

3. How do I care for wheeler manufacturing jewelry?

Wheeler manufacturing jewelry is generally durable, but it’s important to follow basic care guidelines. Avoid exposing the piece to harsh chemicals, extreme temperatures, and abrasive materials. Regularly clean the jewelry with a soft cloth and mild soap.

4. Where can I find wheeler manufacturing jewelry?

Wheeler manufacturing jewelry can be found in a variety of places, including independent jewelry stores, online retailers, and craft fairs. Look for jewelers who specialize in wirework and intricate designs.

5. Can I learn how to do wheeler manufacturing?

Yes, you can learn how to do wheeler manufacturing. There are many resources available, including online tutorials, workshops, and classes. However, mastering the technique requires time, practice, and a passion for detail.

Tips for Choosing Wheeler Manufacturing Jewelry

- Consider the Design: Choose a piece that resonates with your personal style and taste.

- Examine the Craftsmanship: Look for intricate details, smooth finishes, and consistent textures.

- Check the Materials: Ensure the metal is high quality and appropriate for the design.

- Ask About the Process: Inquire about the jeweler’s experience with wheeler manufacturing and their commitment to quality.

- Consider the Occasion: Choose a piece that is appropriate for the occasion, whether it’s a special gift, a statement piece, or everyday wear.

Conclusion: A Legacy of Precision and Elegance

Wheeler manufacturing jewelry embodies a legacy of craftsmanship, precision, and artistic vision. It represents a fusion of traditional techniques and modern technology, resulting in pieces that are both beautiful and enduring. Whether you’re a seasoned collector or a first-time buyer, wheeler manufacturing jewelry offers a unique opportunity to own a piece of artistry that will be cherished for generations to come.

Closure

Thus, we hope this article has provided valuable insights into The Art and Science of Wheeler Manufacturing Jewelry: Crafting Precision and Elegance. We thank you for taking the time to read this article. See you in our next article!